Hey, I’m a complete newbie when it comes to 3D printing. I have a chance to pick up this printer second hand, and I was wondering what the community thinks of the product. Would this printer be decent for a beginner? Thanks!

I love my Ender3 V2. It’s a great workhorse. If you are in the United States you may be able to snag one from Microcenter for $100. It is a good entry point that you can upgrade as you go along. I have added a bl-touch (definitely get one) direct drive, and a dual z axis. But it was making great prints before the upgrades. Also since they are the most common printer parts are easy to find.

Have a ender3V2 as my first printer, buy it, hopefully no second hand issues, use it, enjoy it, but resist the urge to spend time and money upgrading, you want a better printer after running through a few spools, buy a better printer (sovol sv06, perhaps)

only ‘upgrade’ i’ve done is a filament guide and lots of time levelling the bed, frequently.

I might be a bit late with my answer, but overall the ender 3 is a decent beginner printer. I’ve had no major problems with mine.

You and others please note that there are 4 different models of the ender 3.

- ender 3: loud board and stock everything

- ender 3 v2, new screen, silent board, adjustment knobs for belts and a glass bed

- ender 3 neo. silent board, old screen, auto bed leveling (BL-Touch), glass bed

- ender 3 v2 neo: Basically a v2 + neo

IMO the neo is a sweet spot for beginners. It has most of the upgrades people do on their printers, while being cheaper than doing them yourself.

EDIT: just read that you’re buying used. Depending on the price the v2 would be completely fine. Just add bltouch later if you want.

I am the go-to guy for 3D printers for quite a few people. Everyone who has an Ender 3 had them up and running in a short time, and all of them printed out of the box without issues.

I had one guy who fell into the trap of buying every possible upgrade and it took a while for us to get it going with all the upgrades, but other than that, an Ender 3 is a solid first machine.

Sure, it’s not as great as some other machines out there, but these other machines don’t cost <€250 on Amazon.

Anything better than the Ender 3 v2 will get you into diminishing returns territory very fast.

I have a e3v2, and I already have more in upgrades in it than I paid initially for the printer, each one to “fix” an issue I was having - dual z to fix x gantry from sagging, microswiss NG extruder when my regular extruder broke, the “yellow springs” and now a cr touch as I was getting real sick of manual leveling after a year of use. If you buy that printer, you will learn a lot about how it works and how to fix it. It says you’re getting an automatic leveler, but take the time to learn how to manually level. The ABL helps but it’s not a magic bullet. Also, if the 2 rolls of filament you’re getting are open to the atmosphere you’ll want to make sure to dry them, otherwise you’ll learn a whole other aspect of 3d printing that will drive you nuts.

If you want to tinker with the printer a lot, sure. If you want something that reliably Just Works, you’ll probably need to increase your budget. I’ve heard consistent stories from friends that their various Ender 3’s required lots of tinkering or upgrades to make them happy (one who found it so frustrating he gave up twice before finally getting it working ok, and this was with help from our “expert” friend who had lots of experience with Ender 3’s). And consistent stories from friends that their Prusa MK3’s Just Work and they don’t understand what the Ender 3 friends are talking about for how to solve various problems, because they just didn’t happen.

My personal suspicion (owning neither) is that the QA on the Enders is probably not great, so some of them work pretty well and others are miserable. Any given user has no way to tell whether they are doing something wrong, or just got a machine with really poor tolerances. Ender 3’s are really common on support forums like this one, but I’m not sure how much comes from the low price leading to high sales volumes vs. users on average having more trouble getting jankier machines working well. But Ender clearly has many fans so…?

According to a post on the 3dprinting subreddit that was recommending different budget options, they were not recommending the Ender 3 anymore because QA would have in fact went down like you said. (Their name is made, they can cut cost to increase profits now…)

They were only recommending it if you went for the Ender 3 S1 since it had more features than the base Ender 3 / Pro / V2.

I have an older Ender 3 Pro that I modded quite a bit over the years and would also agree this is more a machine if you want to tinker with it. One important thing to note is that almost no upgrades will result in higher print quality when compared to a well tuned base Ender 3. The mods simply made it a bit more reliable IMO or reduce how often I need to calibration it.

I also agree that if you don’t want to tinker with it, get something else. It will be more expensive upfront but if you take a cheaper printer that you mod over time, the cost will end up being similar. But it’s a decision hard to make if you are not sure you will like the hobby, and an Ender 3 or other similar budget printer can still be OK without modding if you don’t mind the limitations.

And if I were to buy a new printer today, I’d definitely go for something better with more features built in that I wouldn’t have to mod to achieve the same functionality.

Ender-3 V2 is a solid entry level printer. I enjoy mine and once I put the “silent” board on it I could print nearly non-stop without any complaints from my wife or kids.

So the upgrades I would suggest are: BL-Touch/CR-Touch “Silent” control board

Nice to have: Dual gear extruder Higher quality PTFE tubing

I don’t have one, but I heard that it is always a great entry point. It is an ender 3 with some improvements. There are lots of YT videos since it is a popular printer.

Seconding what others have said. It’s a good starting printer you can usually find at a low price. It can be rather hands on tho.

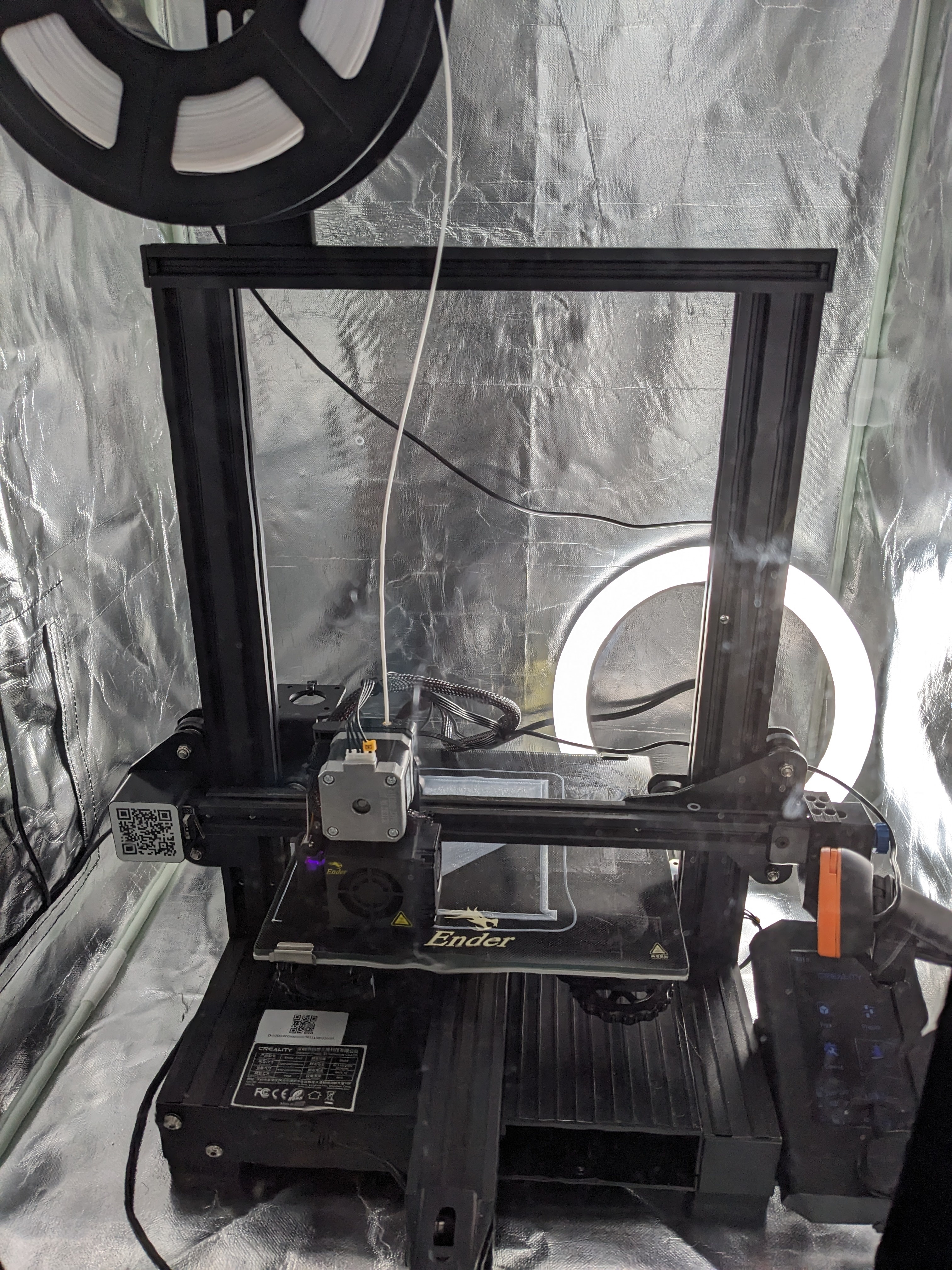

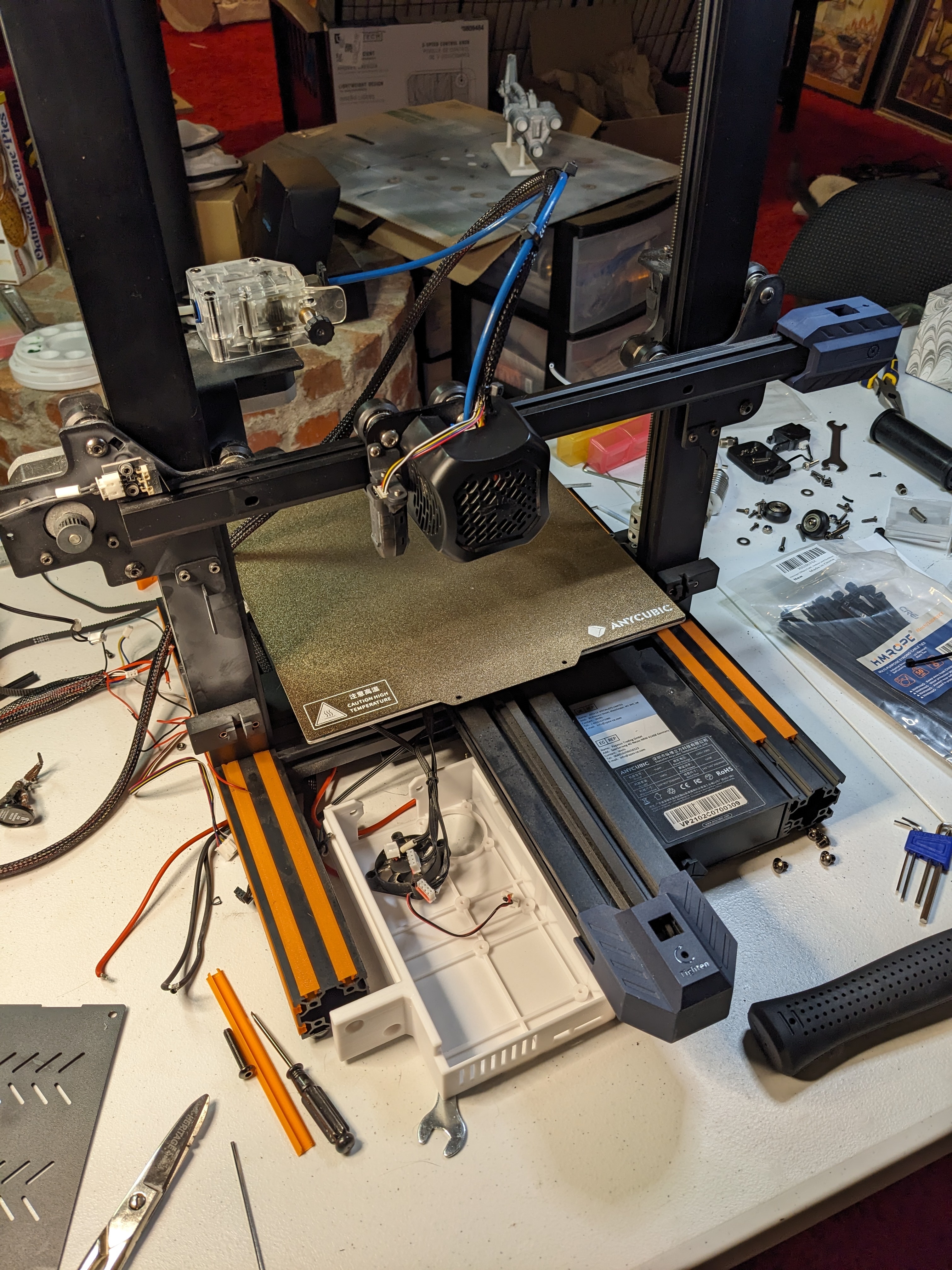

Here it is hard at work making a lid for a motherboard case. I have an Anycubic Vyper that broke so many times (strain gauge) that I am converting it to an Franken Ender 3.

Cool! Since you have firsthand experience, maybe you could give me an idea of whether it’s a good deal. I posted a comment with all the upgrades and inclusions and price above. Any insight would be much appreciated!

These usually go for $200 brand new at Microcenter. So as long as it is in good working order, you are getting all of those upgrades and filament for $25. I would be careful this may be a friend trying to trick you into the hobby!

So here’s what the deal looks like.

Upgrades:

- Direct drive with Sherpa mini-extruder

- Rapido hotend

- CRtouch auto-level

- SKR 3 main board

- PEI bed

- Silicone spacers

- Belted Z

- Klipper firmware

Includes

- Extra nozzles

- Original hotend

- Original main board

- 2 rolls of filament

225.44 USD

Good deal?

I have an Ender 3 V1, so take this advice with a grain of salt.

I can’t tell you if the deal is financially good or not, what I can tell you is what my printer is like and if it has problems.

I’ve had my Ender 3 since 2020, and it’s been both a reliable work horse, and a un-reliable eWaste depending on the week, and how much work I need to do on it.

Out of the box it will work well enough, but without a bed leveler it was difficult to get a good first layer. You have that so you pass the minimum hardware requirements. The other upgrade I bought for it was a silent board upgrade (which you might already have) and a all metal heat break. If you don’t have a all metal heat break, you will need a roll of PTFE Tubing since the end in the hotend will char and the filament will jam over time.

PEI Sheet is good, though if you print with high temps you may want a glass or a G-10 print bed. PEI Stick like Glue to PETG and will rip and destroy your bed.

As for my issues with Printing on the Ender 3. Well the Bowden system will cause for minor inconsistencies across the X-Axis. It took me years to find this out and another printer from Prusa to narrow this down, however it only impacts tiny parts of a print, and the variance is like ±0.005mm. Most people don’t need this level of accuracy so it’s fine, especially if it’s your first printer.

Another issue I have with the auto bed leveling is the accuracy on the level. It only gives you 2 decimal points of accuracy 0.01, however the properly level my bed I found I needed 3, so manual bed leveling might still be required for you. Since I am always too close to the bed, or no close enough while printing.

With my grievances aside (a good 3D printable model will account for a lot of these faults), I don’t hate my Ender 3. the CR-Touch allows me to use beds made out of other materials, rather than steel bed only that I get with the Prusa Mini. I’ve repaired this sucker more time than I can count, from belts to hot ends, to nozzles and more. And all the parts are easily obtainable from Amazon or even locally at my electronics store.

I personally consider the Ender 3 a hobbyist printer, I’ve personally expanded beyond printing for myself, so I needed something more reliable. But if you aren’t printing day in day out 365 days a year, then it’s a solid reliable machine which you will need to tinker with time to time, that is repairable with easily accessible parts. And for the price is cheaper than the alternative.

But there is a reason most print farms and printers use Prusa and (hoping for the long run for these folk) Bamboo Labs.

That’s actually a really good deal if the printer doesn’t show any signs of physical abuse. There are videos available that discuss how to put the original machines together, and this information is still helpful in showing you where key problem areas might occur and things you want to check before trying to use a used printer. At the top of the list I would suggest making sure the frame is square, the X gantry (the one the print head rides on) is square to the rest of the frame, and that the eccentric nuts are all adjusted (these are part of the rollers that allow the X, Y, and Z axis to all slide freely).

A couple to get you started out with – these are for the original version of the Ender 3 but most of the information will still directly apply to the v2 machine. Ender 3 assembly: https://www.youtube.com/watch?v=me8Qrwh907Q Bed leveling: https://www.youtube.com/watch?v=5eqTmb01cBk

The information about bed leveling is critical even if you have an auto bed-leveler. You still want to know how to keep the bed reasonably square to the rest of the frame or the ABL is going to be constantly adjusting itself even for simple prints. One of the key mistakes most people make is to leave the springs (or in your case the silicone spacers) too loose which allows the leveling knobs to freely turn while the machine is printing. This is what causes the common issue of “I have to re-level my bed after every few prints”. When done right, you can easily go 6-12 months without ever having to touch the bed leveling. In my case with still using the springs, “done right” means you get all the leveling knobs tightened all the way, then adjust the Z switch to match that position, THEN proceed with leveling the bed. A lot of people just leave the Z switch where it’s at and adjust the leveling knobs to that level which results in springs that are very loose.

As far as the printer itself goes… I’ve had my original model Ender 3 Pro for 4.5 years now, pumped out a lot of prints over the years, and still find it more reliable and giving better print quality than the $2500 printer we have at work which has auto-everything and still somehow fails. Plus I personally really love how easy it is to do upgrades on this printer which allows me to customize it to my own needs. Even my direct-drive print head was 3D printed!

It’s worth it if you have the time and willpower to invest in the machine. They can print ten jobs adequately and then your bed adhesion can go to hell out of nowhere on the eleventh and you have to spend some time troubleshooting it. There are fewer such headaches at higher price points, but no machine is going to print perfectly every time. I’d recommend making sure you’re able to monitor your print jobs either in person or remotely with a webcam so you make sure you’re not wasting loads of filament and having to clean up or replace parts in the event a print fails.

Ender3 is an outstanding entry point to the 3d printing hobby. It’s open source hardware, so no other printer has cheaper parts. And may be the most common 3d printer, so plentiful modification options and tutorials.

Where’s the source?