#Soldering Tools

Most soldering iron manufacturers make some sort of soldering tools or soldering aids. They are an assortment of little pokers and hooks and forks and pry tools. I’ve looked at them from time to time but all I’ve ever used are the little plastic things that come with Weller consumer soldering irons.

I love these things. They used to have a fork on one end but I find the poker MUCH more useful so I just sanded a blunt one on one end and sharpened the one on the other end. I always have one near and often in my left hand when I’m soldering. I use them to position small components and hold them while I’m soldering them. I push and pry and poke things with them. I like them so much that I reached out to Weller about buying more. They don’t sell them individually but sent me a few in the mail. Awesome customer support!

#Scalpel

The only other thing that I can think of that’s part of my tools and materials is a pair of scalpel handles and blades.

This is a No. 3 handle with a No. 11 blade and a No. 4 handle with a No. 22 blade. I use these for all kinds of cutting and scraping operations. I use them for placing stickers and cutting header strips. They are an invaluable tool. You can buy plastic scalpel handles for $1. These stainless steel surgical handles are less than $10 each. The blades you can buy expired in boxes of 50 or 100 for a very reasonable price. You can even cut thin copper wire with these blades.

I think that’s everything for now. I might think of something else later and come back and add it. I’ll pin this post to the community.

Comments, additions, and questions are welcome.

I remembered another thing!

#Pinchy Things

I have a drawer labelled “TOOLS” and a drawer labelled “PLIERS”. Anything scissor like goes in the PLIERS drawer.

In this picture from left to right are:

Flush cutting pliers. They’re like side cutters or diagonal cutters but they are ground on one side only so you can cut really, REALLY close to the board. The blades are normally fairly soft so you can only cut soft things like copper wires and component leads. You can buy REALLY expensive ones but these are cheap, house brand ones that I buy at Princess Auto three or four at a time. Seriously, I have like 12 pairs. There are 3 pairs in my PLIERS drawer right now. Next are cabling scissors. They look like hell but they are amazing. One blade is serrated so that wires don’t slip out as you cut them. They’re tough as well and can cut through anything short of a nail (though they will cut through some small nails.) Next is a pair of little scissors that I use for cutting labels and things of that type. Tweezers are important for handling small components. I have a stainless steel pair, a squeeze open stainless steel pair, and a ESD safe coated stainless steel pair. The squeeze open ones are awesome because you squeeze them open and the spring closed. You can use them to hold wires or small components while you solder them. Far right is a small pair of cheap side cutters. I use those for anything I don’t want to use my flush cutters for. Their blades are hardened better than the flush cutters so they don’t damage as easily.

Just reading through all of this - awesome stuff! Things I (personally) would add onto this list:

-A small jeweler’s vise (and/or panavise) - makes it super easy to work on smaller boards, and works so much better than a cheap set of helping hands. A jewelers vise can clamp to your desk so it won’t move around at all.

-a fume extractor & safety goggles - safety is #1!

-a small steel dental pick. Sometimes I’ll get stuff stuck in holes on boards and it won’t come out with a solder sucker - sticking a very small, thin dental pick into the hole can push it right out.

-an anti static wristband, if you’re paranoid

-one of my favorite things to use - a DIP removal tool of some sort. I use an iFixit metal spudger - it happens to be the exact width of a DIP and works wonders for either getting them out of sockets or just removing them from boards. Slide it under the chip and just lift.

-one more thing that isn’t a necessity but is definitely useful (and something I’ve seen in your other posts) - a soldering microscope. But - those can obviously be very expensive! Instead, I actually use a document camera (like the ones your teachers may have used if you were born any time later than 2000). They’re still not super cheap but can be had for much less than a microscope on eBay or equivalent. I found mine in a trash bin & it does 12x optical zoom + 8x digital, which is more than enough for almost any soldering I have to do.

I can attach pictures of my tools as well if need be - but for time’s sake I haven’t done that yet. Now… I’m off to go buy some liquid flux, lol

Just reading through all of this - awesome stuff! Things I (personally) would add onto this list:

-A small jeweler’s vise (and/or panavise) - makes it super easy to work on smaller boards, and works so much better than a cheap set of helping hands. A jewelers vise can clamp to your desk so it won’t move around at all.

That’s a good one. I’ve always thought about getting something to hold down my work but never got around to it. I never considered a jeweler’s vice.

-a fume extractor & safety goggles - safety is #1!

Also good ones. I really do need a fume extractor. This is another thing that I’ve thought about but haven’t ever gotten around to doing. Maybe it’s time?

-a small steel dental pick. Sometimes I’ll get stuff stuck in holes on boards and it won’t come out with a solder sucker - sticking a very small, thin dental pick into the hole can push it right out.

Yes. Definitely. I have a couple of sets of things that fit this bill.

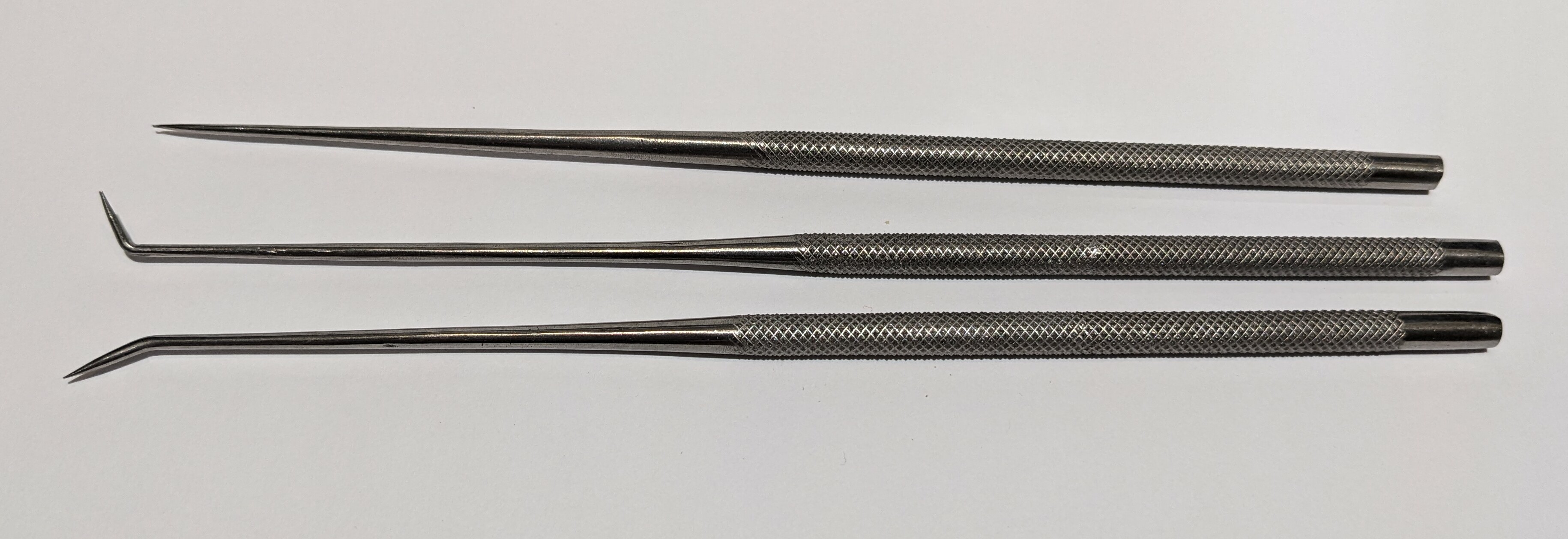

Some dental picks

and some wax carving tools. I don’t carve wax but there are lots of cutting, scraping, prying opportunities with this set.

-an anti static wristband, if you’re paranoid

Great suggestion.

-one of my favorite things to use - a DIP removal tool of some sort. I use an iFixit metal spudger - it happens to be the exact width of a DIP and works wonders for either getting them out of sockets or just removing them from boards. Slide it under the chip and just lift.

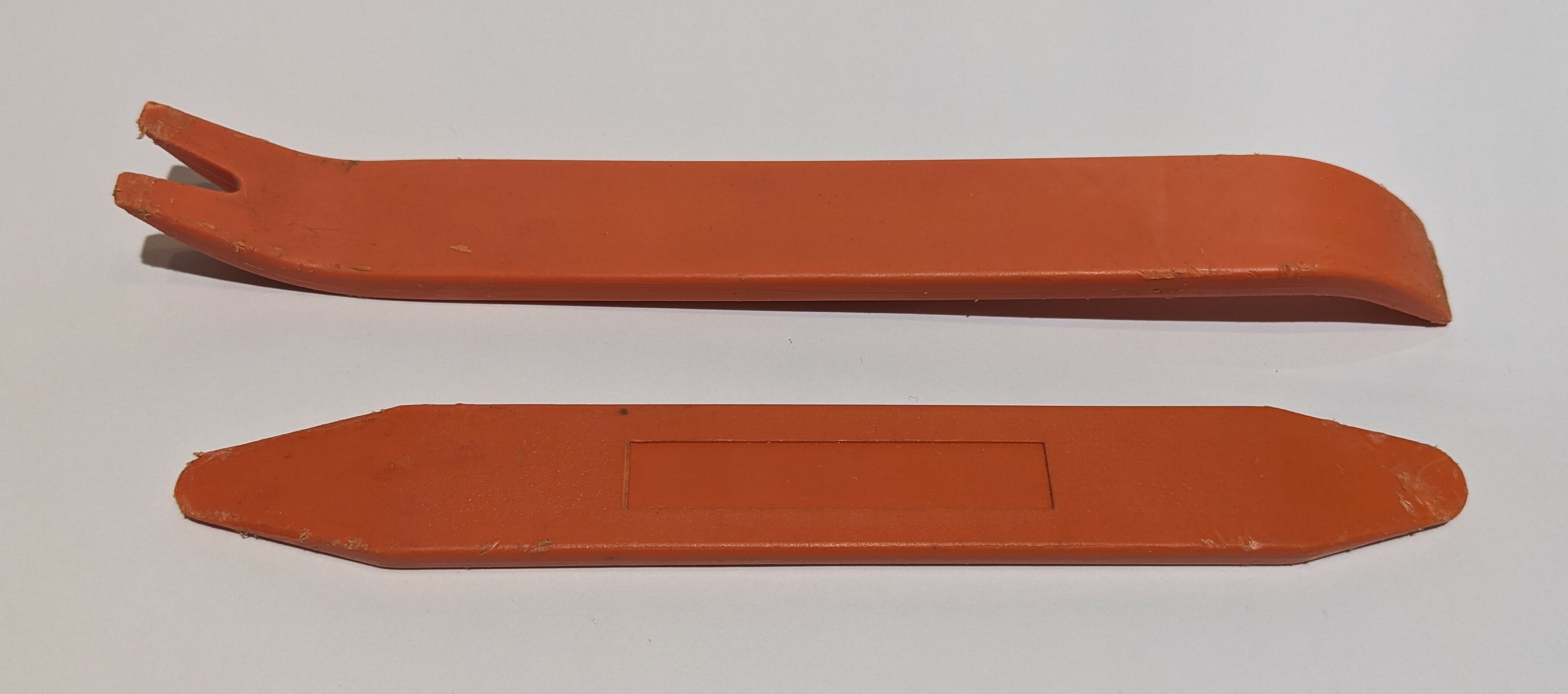

I’ve had a variety of those over the years. From the simple bent metal ones to the ones with the plunger to keep the pull straight. I don’t work with DIPs anymore but I do need to pull things out of breadboards. I work in information security and in my last job I had the need to get into things and back out without people knowing that I had been there. I bought a set of non-marring pry tools at Defcon a few years ago and they are almost always on my desk.

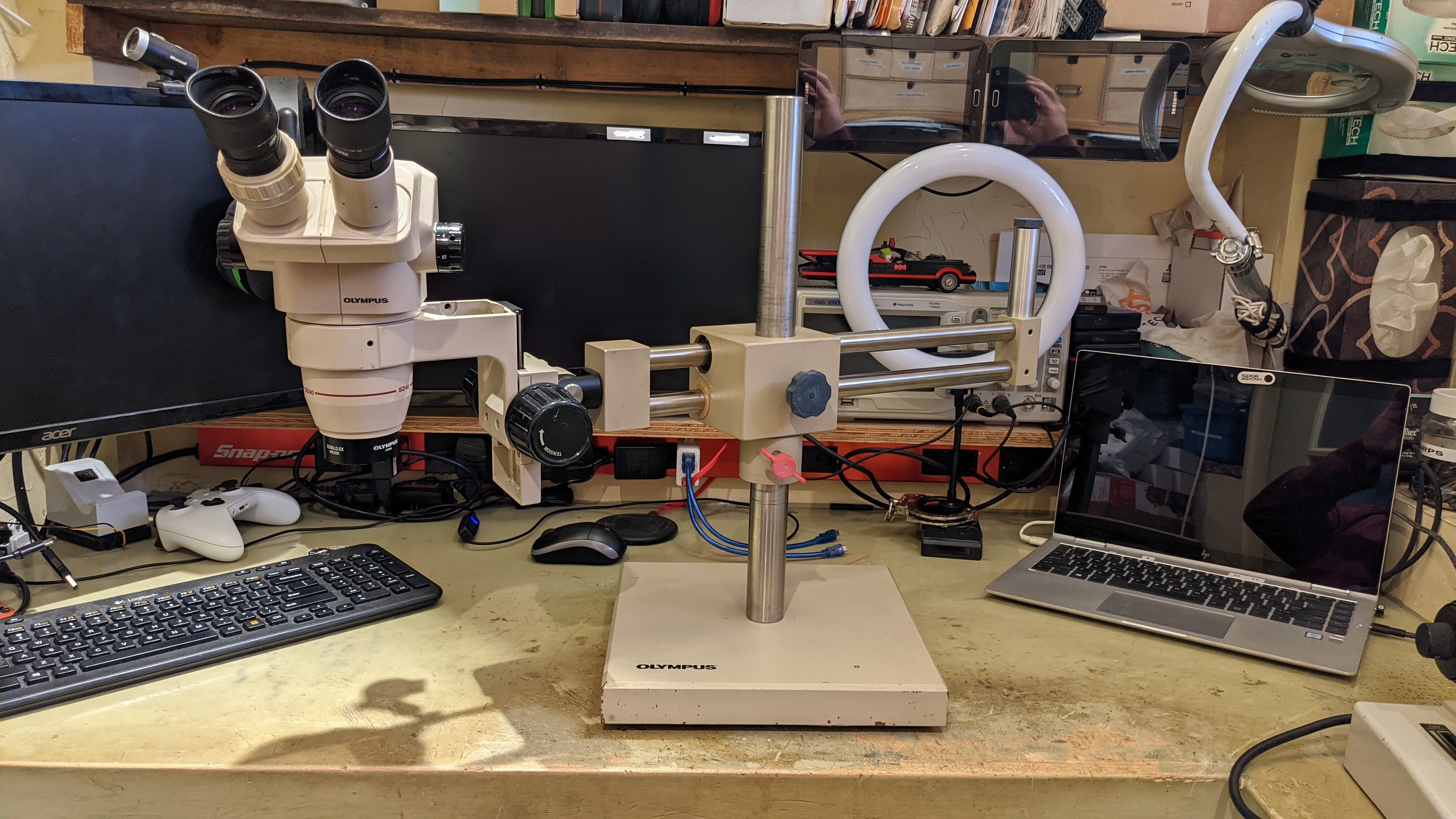

-one more thing that isn’t a necessity but is definitely useful (and something I’ve seen in your other posts) - a soldering microscope. But - those can obviously be very expensive! Instead, I actually use a document camera (like the ones your teachers may have used if you were born any time later than 2000). They’re still not super cheap but can be had for much less than a microscope on eBay or equivalent. I found mine in a trash bin & it does 12x optical zoom + 8x digital, which is more than enough for almost any soldering I have to do.

I bought an Olympus SZ40 on an arm a couple of years ago from a science/microscope store in Montreal that was going out of business. I paid $200. It’s a fantastic scope and I wish now that I have it that I had bought a microscope years ago.

This is a life changing suggestion.

I’ve got a couple of additions. (I had planned to make another post with some more advanced tools like the microscope, oscilloscope, desoldering gun, etc. I should probably do that.)

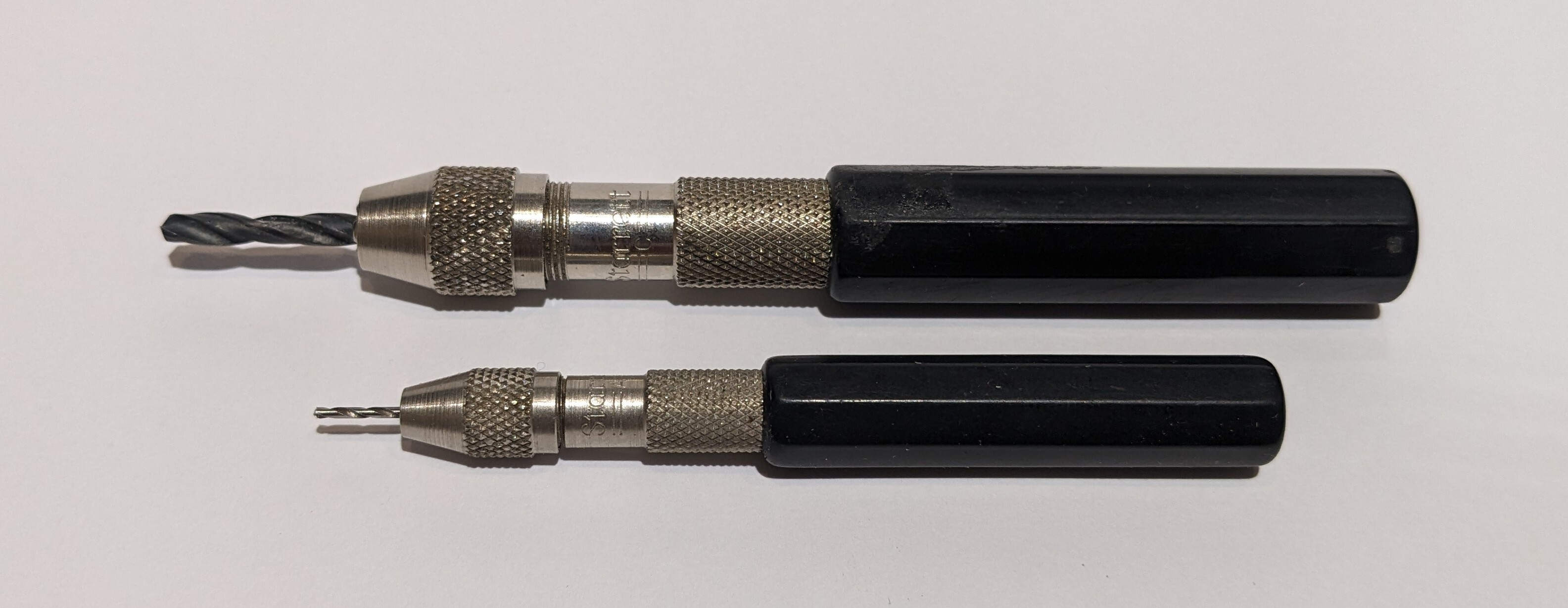

I have a pair of Starrett 166 pin vises that I love. The smaller one is the 166A and the larger the 166C. There are also a B and a D but I find that the A and C meet my needs. In this picture the A has a 0.8mm drill bit in it and the C a 1/8" drill bit. I also have a range of drill bits from extremely fine up to 1/8" that I use for all sorts of things.

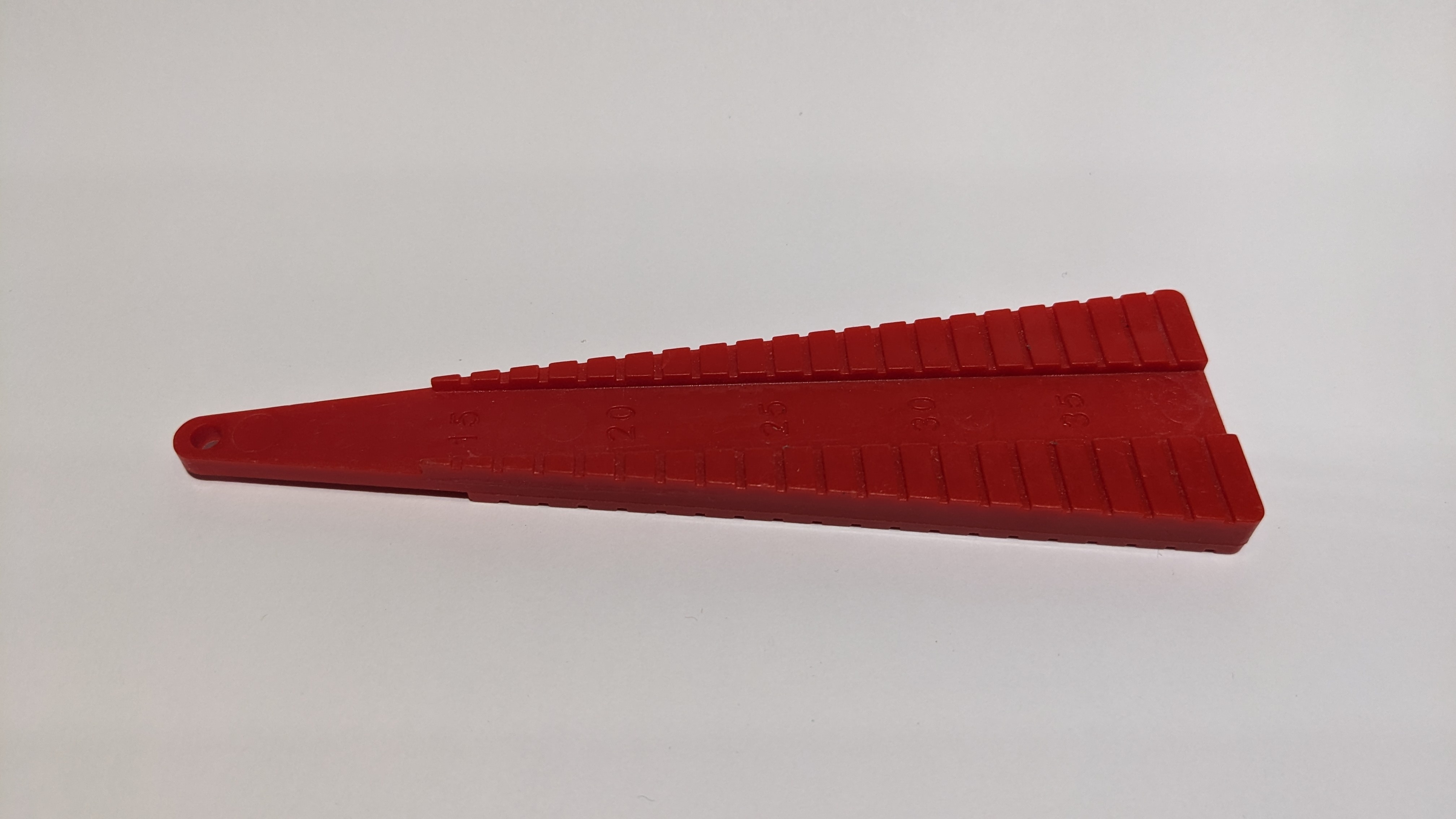

Anyone who is new and doing through hole soldering may want to consider getting one of these bad boys.

I can attach pictures of my tools as well if need be - but for time’s sake I haven’t done that yet. Now… I’m off to go buy some liquid flux, lol

Definitely do. If you make it up in the form of the pinned posts I’ll pin yours as well. Definitely contribute. That’s how we will grow the community.

-a fume extractor & safety goggles - safety is #1!

Do you have a recommendation for a good fume extractor?

I don’t, actually, unfortunately. I took a beefy 12V fan out of an old Dell Precision & run it at about half of the rated current with a wall wart power supply I had in my spares bin. Works super well - just made an adapter from the 4” fan to a 2” flexible duct tube and stick it out the window when I am soldering.

Although, I do have to figure out winter time… it’s getting cold and right now all I can do is pump the bad air into a closet across the room lol. Gonna buy an activated carbon filter or something eventually.

Thanks anyways, I still appreciate the ideas. Even if they’re more MacGyvery than I’m looking for lol.