Total clog with prusament pla in line. Can’t feed anything through even at high heat. Cold pull not possible / filament not making it into hot end to do this.

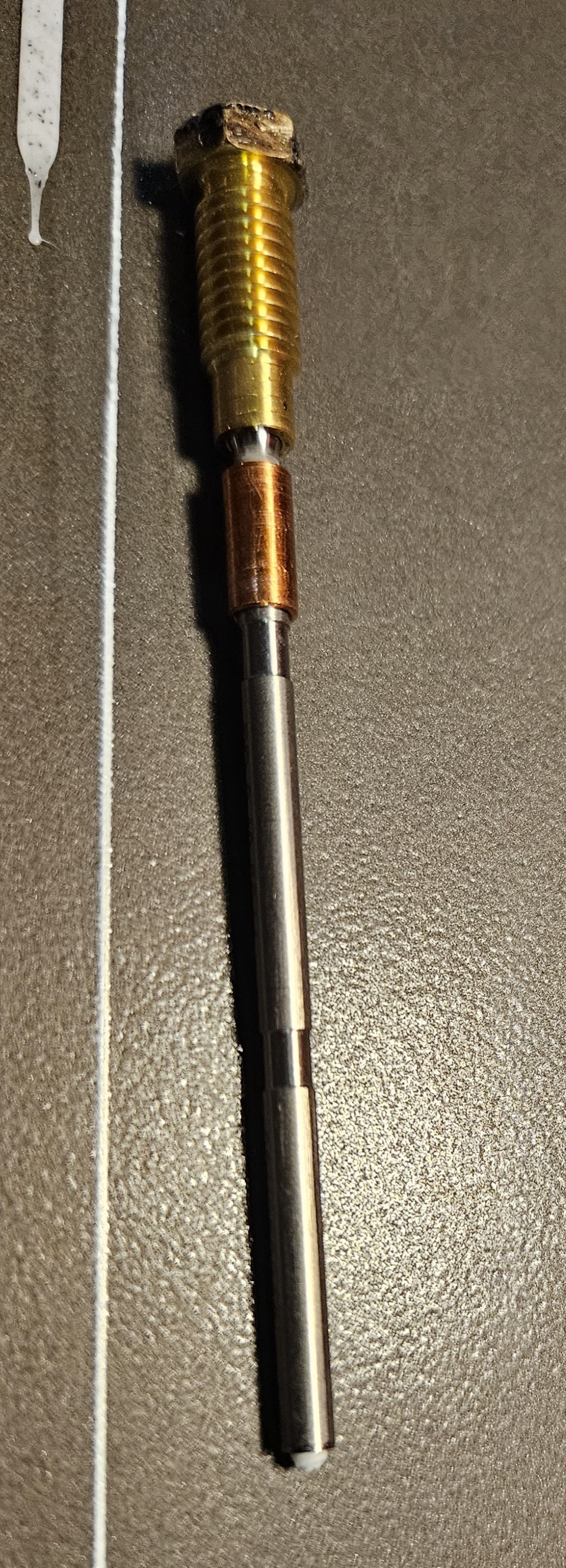

You can see little bit of filament sticking out in photo, but with pliers this just tears.

Should I try heating up the whole hot end tube with a soldering iron to see if I can liquify the clog out?

Any other ideas? I can’t find many good resources about what to do in this situation online.

Also, obviously needs to get cleaned up a bit, but does picture of my hot end tip look pretty ok? Do I need to bite bullet and get a new hot end? If so, are Amazon off brand replacements ok, or do I need to wait for one to get shipped from prusa?

Thank you

I do not own a Prusa, so take this advice with a grain of salt, but should be universal advice.

Slowly heat the tube up, starting from the nozzle end. You can use a soldering iron but I’ve always used a small handheld blow torch on low, much quicker and no chance of plastic-ing my iron.

Once the filament starts increasing in temp, it will start to expand, this usually pushes a chunk of solid filament out the end. Use some pliers to slowly and gently pull the filament out.

The ultimate goal is to heat the filament up just enough to push that bit out and soften the plastic inside. When you pull out the solid end, you want to to it slowly enough that the softened filament “strings” out with the solid piece. If you’ve ever pulled a glob off your nozzle and watched it slowly peel off as it strings away you’ll know exactly what I mean.

You won’t get 100% of the clog out this way, but if you do it right you should at least get it cleared enough to be able to stick a cleaning tool down there and get the rest out. That being said, I’ve always torched the hell out of my metal hotend parts (nozzles/ heat blocks and throats starting to glow red) to clean them and never had issues come from it, but your Prusa is a bit fancier and much more expensive than my barbarian of a printer, might be more sensitive to the minor changes that may occur from such heat cycles.

Shoot me a message or reply if you still need help. Clogs are my nemesis.

Blowtorch will heat this up way too hot.

Try to get it to a high enough temperature to insert filament to do a cold pull and repeat…

Electrical heat gun (paint stripper) is hot enough. Gas based torches will change the stiffness of your material and you will regret it.

Gas based torches will change the stiffness of your material and you will regret it.

Any particular reason? As explained above I regularly heat my hotend components to the point that they emit a light glow to remove all the plastic particulates and have never had an issue related to it.

You’re affecting the hardness of the metals if you’re heating them to glowing point, because you’re heat treating them. The actual consequence is probably minimal, but you could potentially be softening the brass tip which could affect the rate of wear. From skimming a few random online sources, brass is only work-hardened, so if the nozzle was previously hardened, you’re un-hardening it (apparently quenching from high heat only hardens ferrous metals like iron and steel?).

I see. Nozzles are cheap enough (when you get the cheap Amazon ones I do) so that I don’t mind possibly eventually buying a few more to save myself massive amounts of time now, but it’s good to know what the actual problem is

To be clear, I’m trying to pull it out the wider back end of the tube or pull it out the nozzle tip?

Out of the wider backend side.

Heat the nozzle end, it will create essentially a bubble at the side and start pushing everything out the other end (some will come out the nozzle, but since it is such a narrow opening it is easier for the filament to flow backwards), as soon as you see it start to come out the back end stop applying heat and gently pull on the part the gets pushed out.

If you go too quickly and separate the solid bit from the molten bit, quickly push it back in and try again. If you can’t get the two pieces to connect, apply a little more heat and keep trying.

If cold pulls won’t work get a new nozzle. Filament of choice for this procedure is Nylon.

One of the alternatives could be THF to dissolve the plastic and go from there. Don’t know what Prusa charges for nozzles but it can’t be that bad to make this procedure worth it. After all it is a Prusa and not some industrial machine.