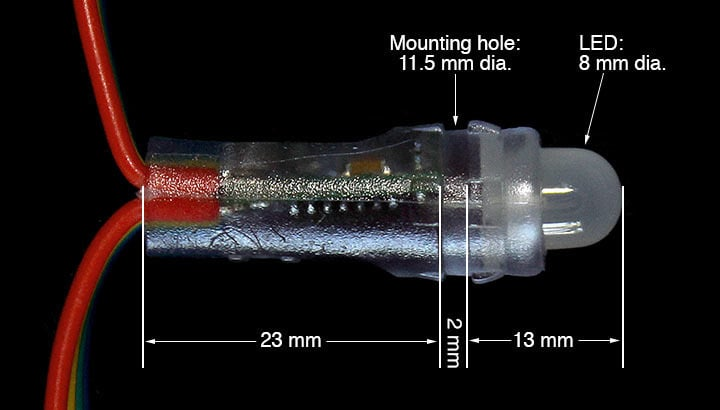

I’m in the process of replacing all my single-color christmas lights with addressable RGB LEDs, but the 12mm “bullet” form factor of them is different from the traditional incandescent mini lights, the 5mm wide angle LEDs, etc.:

You’d think they’d make C6/7/9 bulb covers that attach to them, but I have yet to find any for sale, anywhere. As such, I want to 3D print some, along with 12mm bullet pixel-sized replacements for my snowflake lights:

What’s some good filament I can get that will be reasonably clear and stay that way (without yellowing or getting too brittle) for several years’ worth of Christmas seasons, despite UV/rain/cold exposure?

(Bonus question: anybody know a good way to model the facets in those “strawberry” lights? The C7 bulbs on Thingiverse, such as this one, are all smooth, LOL.)

Edit: by the way, to be clear (pun intended): I don’t need optical clarity like the lens guy; scattering the light is fine. (In fact, doing that on purpose is kind of the point of modeling a faceted C7 bulb instead of a smooth one.) I just want to make sure that whatever part of the filament that doesn’t manage to be transparent is white, not tinted some dingy color.

I do happen to have some Inland “natural” PLA laying around and did a test print in that. It’s not too bad – only a little bit yellow at the wall thickness I’m using – but I fear for how it will hold up over time.

I mean, you’re probably not wrong, but what’s the alternative? It’s not as if I’m going to injection-mold them or machine them out of a solid block of plastic.

…

[sigh] Damn it, now you’ve got me researching DIY injection molding and rotomolding (once I finish writing this). Thanks a lot! 😠

Thanks for that video link; it was informative.

Regarding transparency/translucency: before even posting this thread, I had already done a quick-and-dirty test print of a C7 bulb cover with some Inland “natural” PLA I had lying around and “normal” settings – not even really dialed in for my new printer at all, let alone customized for maximum transparency – and it was fine (except for being slightly yellow). It’s only a 2 perimeter thick shell, after all.

Heck, I might drop that down to one and use spiral vase mode, if I can figure out how to print the lugs that lock into the groove on the pixel in that mode, instead of a solid bottom layer.

Regarding lighting durability/water-tightness: the way these bullet pixels work is that the hole in the casing where the wires come in is completely filled with potting compound (at least 1/4" from the outside to anything conductive). Also, I’m doing all my wire splicing with marine grade solder seal heat shrink connectors. I’m pretty sure I could run the lights submerged and they’d be fine.

The things I’m printing are just decorative covers to diffuse the light into more interesting shapes. They have nothing to do with protecting the strand itself, and the worst that could happen if water gets in them is that they might get moldy or something.