When I started soldering everything was big and had leads that went through holes in the board. You inserted the leads, bent them over to hold the component, flipped the board over, soldered everything, and trimmed off the excess leads.

Now I’m soldering things down to 0402 SMDs (1/4 the size of the smallest component in the picture) using a needle point soldering tip and a microscope.

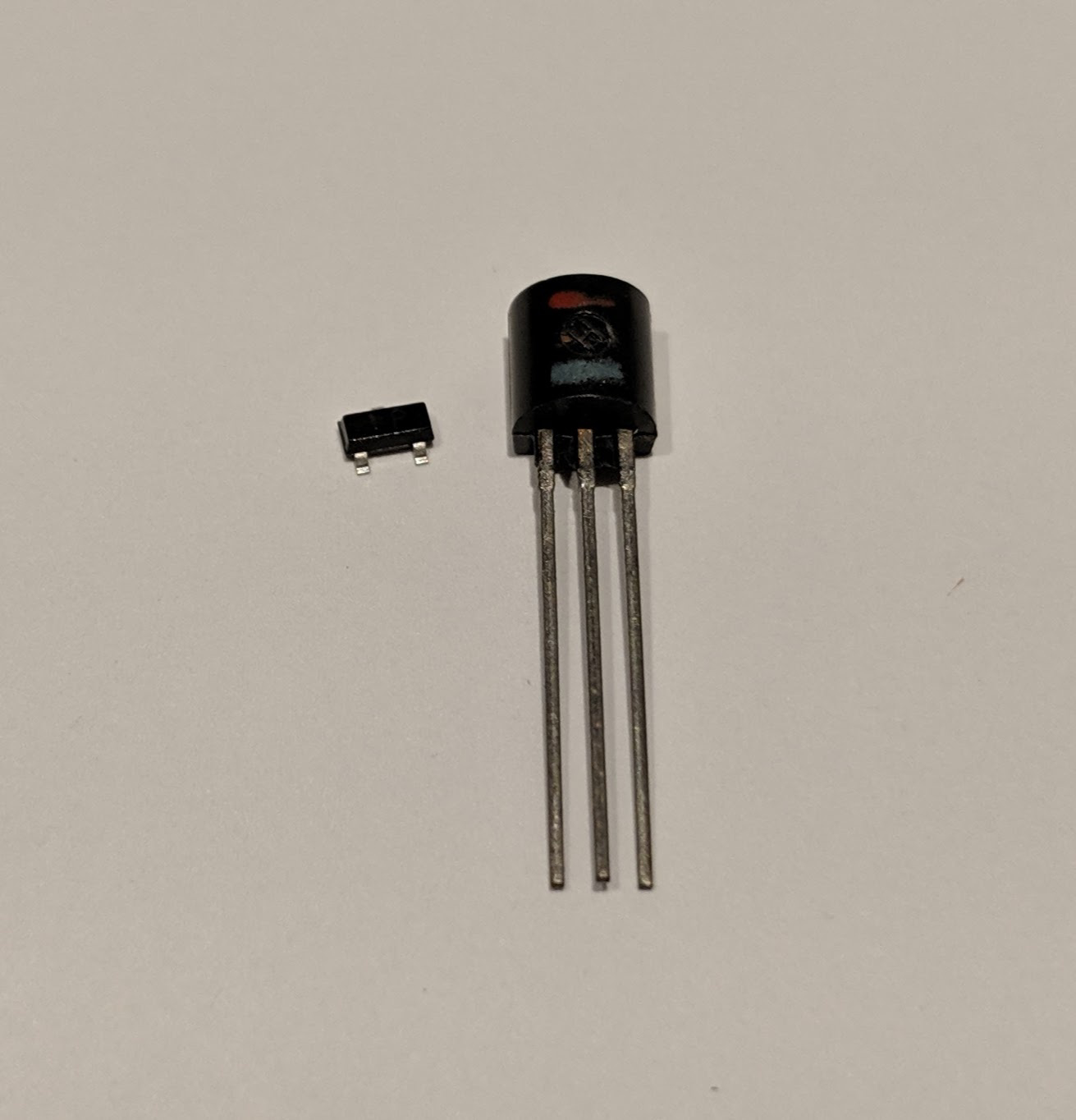

A pair of 2N2222 transistors, one SOT23 and one TO-92.

It is, though the process did start ages ago. The SNES from 1990 already had all the chips and most capacitors as SMDs, and the 1996 N64 motherboard is with the exception of the power LED entirely surface mount. I’d guess the reason for the recent disappearance of through hole devices is to with development of cheaper pick and place machines and labour cost increases - it’s finally cheaper to get one of those to use with SMD components than it is to hire a warehouse full of labour to hand assemble your cheap thing from THD parts.

Also 0402 is an annoying SMD size code, as it’s one of the two (other being 0603) that exist in both imperial and metric sizes - it can be 0402 metric, i.e 0.4mm x 0.2mm which is 01005 imperial, or 0402 imperial which is 1005 (1.0mm x 0.5mm) metric.

I’ve repaired several handheld devices from the era. The Atari Lynx had a bunch of SMDs. So does the NEC TurboExpress. I just sent out half a dozen NES which thankfully were mostly THT. I have a couple of SNES and a couple of N64s out there waiting for me.

Those boxes are the reason I upgraded from the Weller WESD-51 to the Hakko FM-302. I really need tweezers for SMD rework.